Surgical Needles Manufactring

Precision Wire Straightning and Cutting Machine

High speed spinner with variable frequency controller are used for Wires sizing from 5 mm to 150mm by manual length setting

Cutting is through motorise eccentric cutting .Complete centralise controlled electrical panel.

| Wire capacity | 0.4 to 1.6 mm max |

| Components length | 5 mm to 2000 mm* |

| Cutting | Motorised automatic |

| Main motor power | 1.1 kw |

| Cutting motor | 0.75kw |

| Pneumatic air | 6 Bar |

| Power | 430V, 3 Phase |

* Length depends on wire diameter and wire hardness

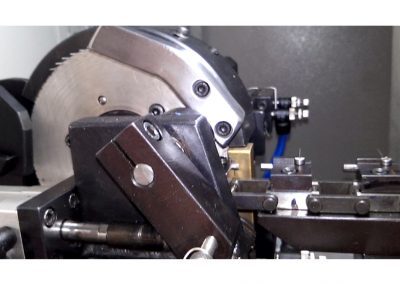

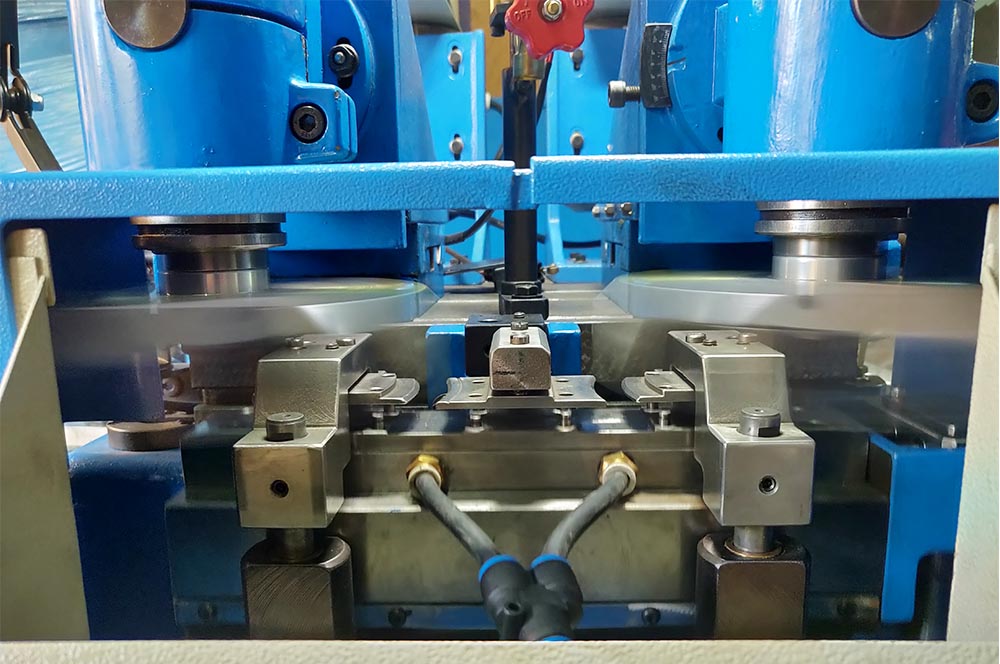

NEEDLE NOSE ROUGH GRINDING MACHINE

Grinding wheel runs bearings on adjustable slide covered safety Pressure wheel speed can controlled by frequency controller Needle feeds continues through speed controller Table tilting facility+/_10 degree Chute for duct collector. Complete centralise controlled electrical panel.

| Grinding dia. capacity | 0.5 to 1.6 mm max |

| Components length | 26 to 120 mm |

| Grinding wheel size | dia.300x120T |

| Pressure wheel dia | 200 mm |

| Grinding wheel speed. | 1400 rpm |

| Pressure wheel speed | 0 to 60 rpm |

| Needles feeding speeds | Auto Feeding |

| Grinding wheel motor capacity | 2.3kw |

| Pressure wheel motor capacity | 0.75kw |

| Needles feeding motor capacity | 0.18kw |

| Power | 440V, 3Phase |

NEEDLE NOSE ROUGH GRINDING MACHINE

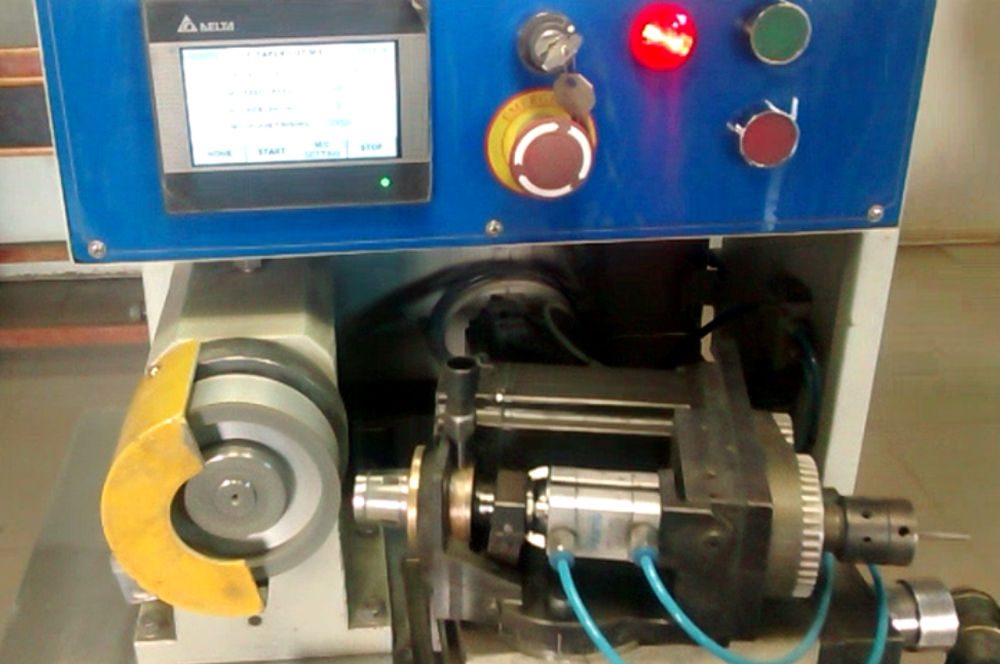

NEEDLE DRILLING MACHINE

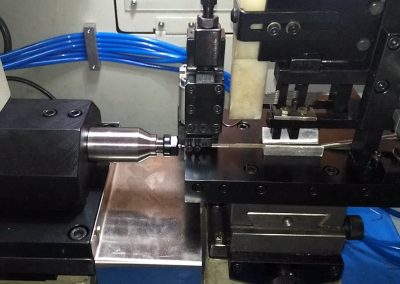

Customise motorised Drilling spindle cartridges 20000rpm with variable speed drive of.

Servo controlled spindle head slides feeding arrangement with PLC & operating system on HMI.

50 Lts capacity microfiltring compartments tank,10 lts delivery capacity ,8kgf pressure cutting oil supply for centring &drilling operations.

Reputed brand machined precision Ball screw and nut Dia 20mm and 15 mm LM guide ways for smooth sliding of both slides.

Pnuematic component feeding.

Component guided on ‘V” guide and clamp by pneumatic clamps.

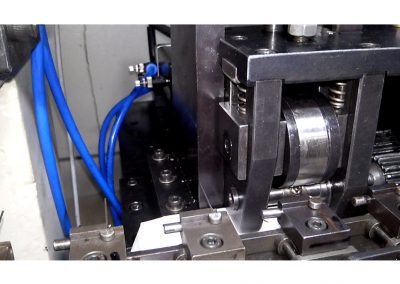

CNC TRIANGULAR NEEDLE LAPPING MACHINE

Grinding main spindle with RHP bearing

Servo controller X axis slide on hiwin ball screw and LM guide ways Component index through Servo controlled motor

Hiwin/PMI Ball screw and LM guide ways for smooth sliding Pneumatic operated component holding unit Wheel dressing attachments Dust collecting chute up to dust collector Two servo motors controlled through PCL and HMI. Complete centralise controlled electrical panel

CNC TRIANGULAR NEEDLE LAPPING MACHINE

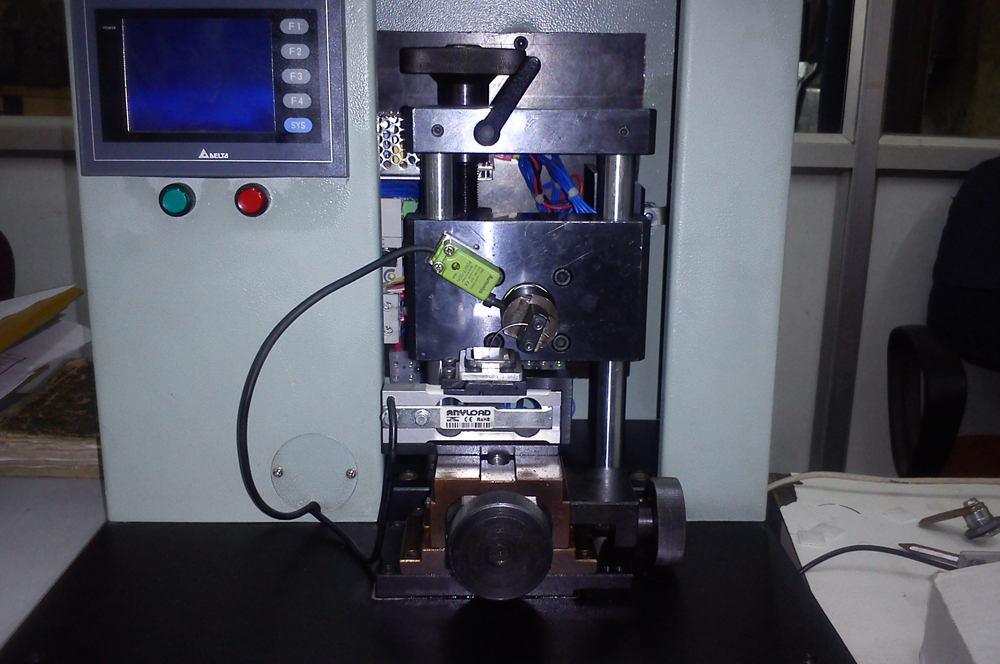

NEEDLE PENNATRATION TESTING MACHINE (Economy module)

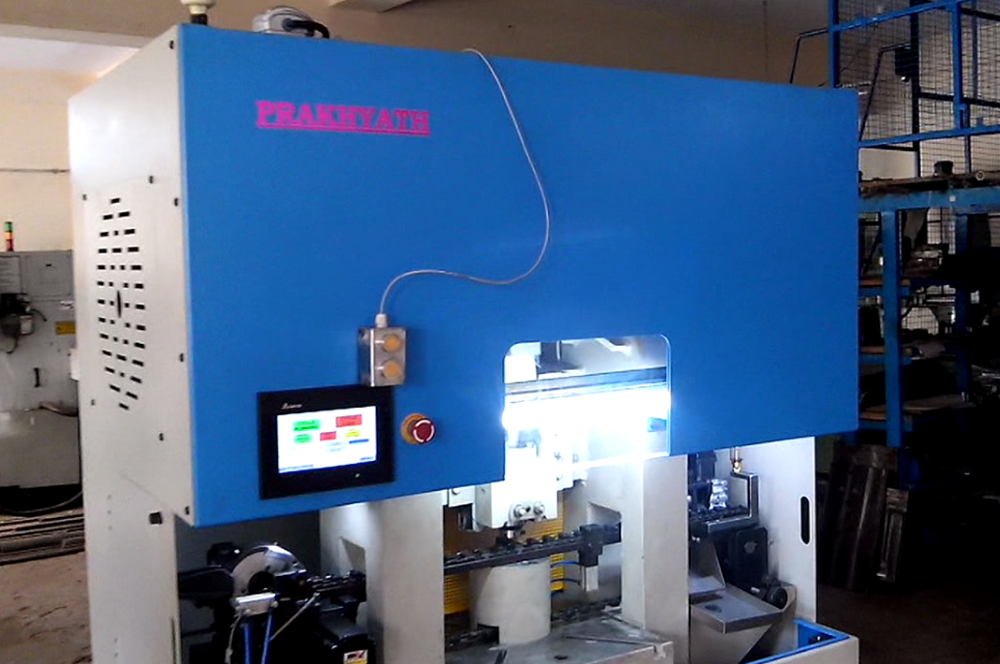

Needle Flattening and Bending Machine

Auto feeding for flattening and bending process. This machine is capable to process needles with diameter from 0.6mm to 1.2mm and length from

18mm to 64mm. Depending in the size of needle, the machine can process 15-20 needles per minute. An user friendly 10″ HMI is provided

for easy setting of the machine. PLC based operation with servo motors for feeding and bending process.